Test & Measurement

Enabling New Capabilities for Instrument Manufacturers

Exxelia Micropen Technologies has material science and design engineering expertise along with a proven track record resulting in high-precision, robust, smaller, and smarter instrumentation devices.

Exxelia Micropen’s printing technology enables precision and repeatability required by modern measurement and detection equipment. A component designed from scratch, new versions with increased functionality, or becoming a second source provides a level of service and performance unmatched in the instrumentation market.

Products Features May Include:

Products Features May Include:

- Unmatched Design Flexibility

- Superior Linearity and Stability

- Robustness and Ruggedness

- High Ohmic Values

- Low Noise

- Shrink product footprint

- TCR tuning

- Built-in feedback

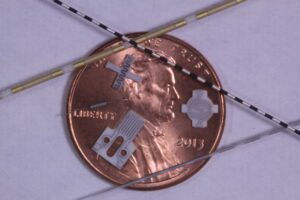

Custom Designed Detection Components

Only Exxelia Micropen Technologies has the material science expertise, design engineering expertise and proven success to drive to even more high-precision, robust and smaller instrumentation devices.

Custom Designed Heated Components

Only Exxelia Micropen Technologies is able to offer end-to-end design engineering, product development and fabrication in partnership with instrumentation companies, helping to bring products to market with increase speed, cost efficiency and reliability.

Only Exxelia Micropen Technologies is able to offer end-to-end design engineering, product development and fabrication in partnership with instrumentation companies, helping to bring products to market with increase speed, cost efficiency and reliability.

- Alumina

- Stainless Steels

- Glass/Pyrex/Quartz

- Polymers

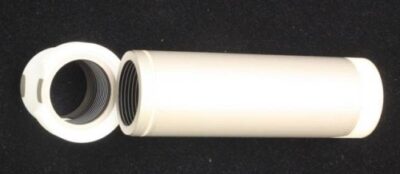

Custom Shaped Resistors

Only Exxelia Micropen Technologies has precision printing capability for odd topologies, i.e. inside and 3D printing, on any ceramic, metallic, glass, or plastic materials, enabling instrumentation design engineers to push beyond existing boundaries with a form factor otherwise unachievable.

Only Exxelia Micropen Technologies has precision printing capability for odd topologies, i.e. inside and 3D printing, on any ceramic, metallic, glass, or plastic materials, enabling instrumentation design engineers to push beyond existing boundaries with a form factor otherwise unachievable.

- 3 Dimensional (3D printing)

- Cylindrical – Inside and outside

- Small to large plates, tubes and rods

- Custom MELF